MUCC Initiates Commercial-Scale Ammonia Combustion Demonstration Test in the Cement Manufacturing Process – World's First Utilization of Carbon-Free Energy for Decarbonization in Cement Manufacturing –

Feb 28, 2025

Mitsubishi UBE Cement Corporation (“MUCC”, Head Office: Chiyoda-ku, Tokyo; President: Makoto Koyama)commenced a commercial-scale demonstration test with a cement kiln (combustion furnace)*¹ and a calciner*² at Ube Cement Plant (Ube City, Yamaguchi) using ammonia, a carbon-free energy, as a heat energy source.

In 2023, we initiated an ammonia co-combustion test with actual equipment at the Ube Cement Plant [1]. Subsequently, the project was selected for Yamaguchi Prefecture's FY2023 Carbon Neutral Complex Development Promotion Subsidy. In collaboration with UBE Corporation, which supplies ammonia to us, we proceeded with the installation of a test facility for co-firing ammonia in the cement kiln and calciner at the Ube Cement Plant. With the successful completion of this project, we have now commenced the world's first commercial-scale demonstration test using actual cement production equipment. To date, we have established a prospect for replacing 30% of the calorific value of coal with ammonia in the cement kiln. For the calciner, we plan to complete the test by the end of fiscal 2025 with the aim of achieving the same 30% replacement ratio.

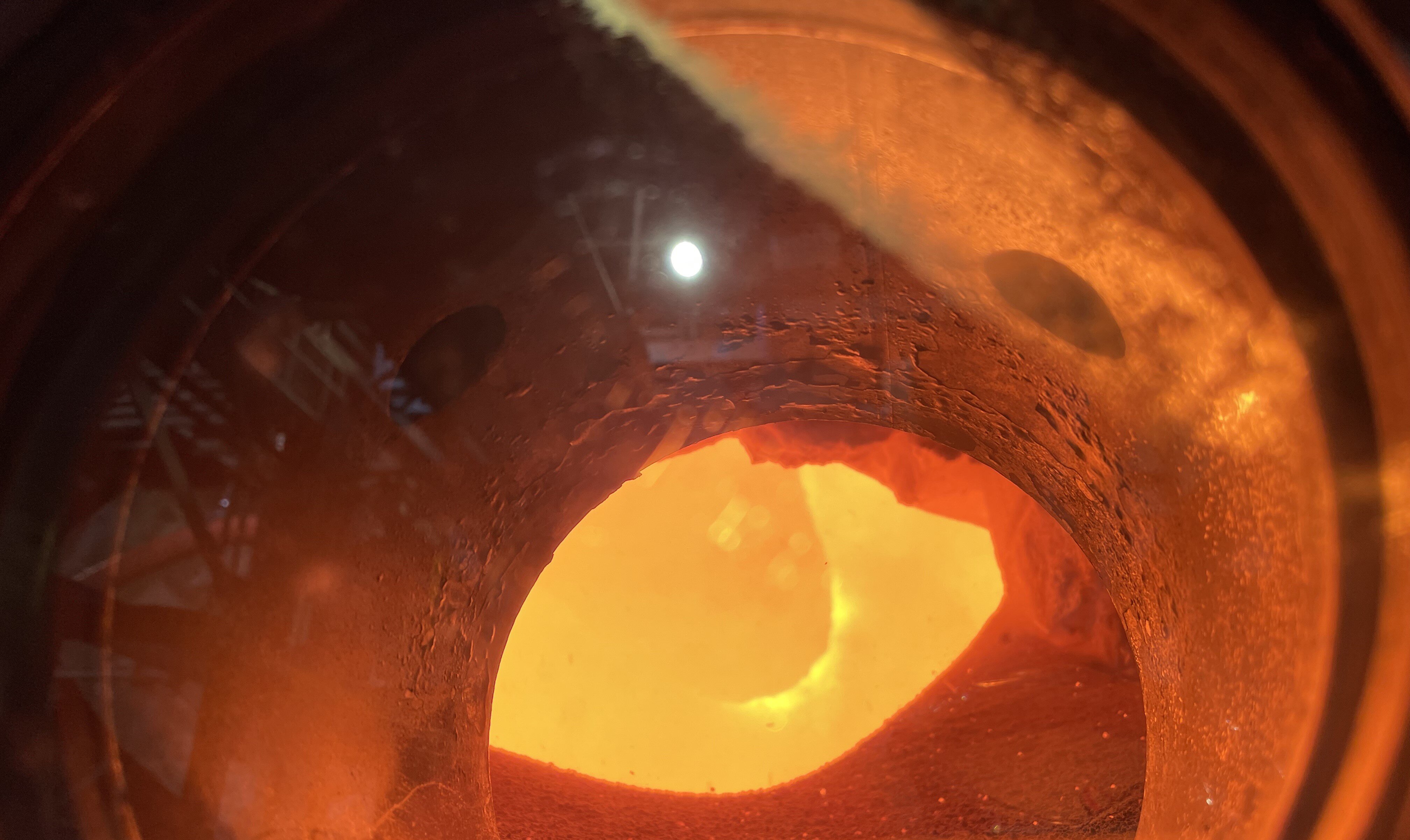

Flame of a cement kiln burner during ammonia co-firing

For the decarbonization of the cement manufacturing process, one of the most effective ways to realize carbon neutrality is to transition from fossil-derived thermal energy sources, such as coal currently used in cement kilns and calciners, to carbon-free energy. Ammonia is attracting international attention as a next-generation energy source that emits no carbon dioxide during combustion. This marks the first instance worldwide in which ammonia has been utilized as a thermal energy source for cement burning. To prepare for future ammonia utilization, we have conducted research and development efforts, including ammonia combustion experiments using small combustion furnaces and optimization studies of ammonia combustion with computational fluid dynamics (CFD). These accumulated findings have significantly contributed to the current demonstration test. Moving forward, we plan to conduct ammonia combustion tests in cement kilns and calciners on a commercial basis, utilizing waste plastics and other waste materials jointly as thermal energy sources. Through these efforts, we aim to accumulate operational expertise in ammonia utilization.

We position global warming countermeasures as one of the highest priorities within our Group strategy. Starting with this demonstration test, we will adopt new technologies to achieve carbon neutrality and continue our efforts to become a leader in the industry.

Reference:

[1]Press release issued by MUCC on April 5, 2023

*(1) A kiln for producing clinker, an intermediate product of cement, by burning blended raw materials such as limestone and clay at a high temperature of 1,450°C using coal or waste as a heat energy source.

*(2) A furnace in which blended raw materials are heated to approximately 900°C using coal, waste, or other heat energy sources to facilitate the decarboxylation reaction of limestone in the raw materials as a pre-process of buring in a cement kiln.

For Inquiries Regarding News Releases

Iino Building, 2-1-1 Uchisaiwaicho, Chiyoda-ku, Tokyo 100-8521

Corporate Communications Office, General Affairs Dept.

TEL